Personal Report of

The Sixth TRIZ Symposium in Japan, 2010

on Sept. 9-11, 2010, at Kanagawa Institute of Technology , Atsugi, Kanagawa, Japan

Dec. 8; Dec. 14, 2010; Feb. 28, 2011

Personal Report of |

|

| Held by the Japan TRIZ Society, NPO, on Sept. 9-11, 2010, at Kanagawa Institute of Technology , Atsugi, Kanagawa, Japan |

|

| Part B. Methodologies in TRIZ | |

| Toru Nakagawa (Osaka Gakuin Univ., Japan), Dec. 8; Dec. 14, 2010; Feb. 28, 2011 |

|

| [Posted on Dec. 30, 2010; Mar. 13, 2011] [Updated: Sept. 25, 2011] |

For going to Japanese pages, press buttons. Japanese translation of this page is not scheduled.

Editor's Note (Toru Nakagawa, Dec. 8, 2010)

This page is Part B of my Personal Report of Japan TRIZ Symposium 2010. Please see the Parent page

for the overall description of the Symposium and the general introduction to the Personal Report. I am thankful to the Authors for their permitting me to quote their slides here for introduction. Click here for the PDF file of this page of Personal Report.

(14 pages, 1.3 MB)

The following table shows the presentations to be included in this part. But currently only the top two articles are reviewed. (Since my reviewing work is much delayed, I have chosen to work on selected articles first independent of the topic categories. See the parent page.) (Dec. 8, 2010)

Editor's Note (Toru Nakagawa, Feb. 28, 201): I have just finished writing this Part B, with so much delay. I am now going to get the permissions by the Authors for me to quote their slides, and to post this Part B on Mar. 13, 2011.

[Note (Mar. 13, 2011): The presentation by Yoshiharu Isaka has been moved to Part D (Case Studies in Industries). ]

[Note: As shown in the right-most column of the table, I have prepared individual HTML pages of several selected presentations for the purpose of wider circulation. Each presentation has English and Japanese pages containing (Extended) Abstract, presentation slides, (full paper), and Nakagawa's introduction. (Sept. 25, 2011)

]

Part B. Methodologies in TRIZ

Manabu Sawaguchi (Waseda Univ.) [JI04, L-2] gave a 'Special Interest Lecture', i.e., an invited lecture (60 minutes) on a topic requested by the Symposium organizers, with the title of "Application of TRIZ for Product Planning – Development of Innovation-oriented TRIZ –". Professor Sawaguchi recently moved from SANNO University/SANNO Institute of Management to Waseda University. The Author's Abstract is quoted here first:

It was found from the result of my previous study that Japanese manufactures are confident in both “Quality Control Techniques” and “Development Power of New Technologies”, in the meantime, face challenges in connection with both “New Product Panning System” and “Innovation Power”.

However, Japanese manufactures should not continue “catch-up strategy”, which always focuses on high quality of product with reasonable price to insure product value, because they have to avoid a comeback by developing countries like “BRICs”. That is to say, BRICs have an ability to realize “high quality of product with low cost” already. Under the circumstances, they are out of options but to be “a front runner” in overseas markets, implementing “Product Innovation” to create innovative new products effectively.

Therefore, I think that it’s very important for them to build up effective “Innovation Oriented TRIZ=Systematic Innovation Approach (SIA)” with utilization of “limited Management Resources”. Let TRIZ now come to “this field” (to realize a front runner strategy) as “a big role” to build up “SIA”. In order to realize “SIA” based on TRIZ, I want to introduce “a model of SIA”, which combines TRIZ method, some marketing techniques and functional analysis in VE to plan and develop innovative products systematically, in this presentation.

The Author starts his talk with his questionnaire survey results on the features of Japanese manufacturers. He obtained 145 answers from 82 participants at his MOT seminar and 63 participant at an pan-industry social event. They are mostly engineers and managers in manufacturing industries. First question was the evaluation (in the points from 1 to 5) of their company's strengths in 11 aspects. The slide (right) demonstrates the top 3 highly-evaluated aspects and the worst 3 aspects. With these results, the Author shows at the bottom half of the slide the general structure of Japanese manufacturing industries. |

Japanese manufacturing companies are confident in their brand images and product development and R&D capabilities, but not much in the structure of new product planning stage. The Author interprets these facts with the historical background as shown in the slide (below-left). The slide (below-right) summarizes well the history of Japanese economy for these 50 years and characterizes the images of engineers required for each stage. They are: Field-oriented engineers (with IE and QC), Cost-conscious engineers (with VE and Taguchi Method), Customer-oriented engineers (with QFD and CS), Environmental-conscious engineers (with 3R and Environment assessment), and Future-oriented engineers (with New generation product, and Risk management). General trend is the decrease in the weight of Improvement while the increase in Radical Innovation.

Then the Author goes ahead to discuss the nature of Innovation. The slide (right) is constructed from the opinions of 45 engineers working at Japanese big manufacturing companies.

Now the focus is how to develop new product/services. In the following two slides, the Author discusses on the basic process of ideal new product development. In the planning stage, technology prediction with marketing should be done. (1) By future prediction activities, scenarios focusing on near future should be created. Then (2) new product planning need to be designed. In the development stage, Design to cost with solution of technical contradiction need to be achieved. Thus (3) basic concept of new product should be designed. |

Then the Author examines the nature of Innovations by using "Best 10 Big Hits" in recent Japan. As shown in the slide (right), the Author first selected "Best 10 Big Hits (form 2000 to 2008)" from "Nikkei Trendy" journal by using some criteria. And then 'Best three' and 'Best one' of them were voted by 168 students and by 28 businesspersons. These voting revealed essentially the same results, the Author says. E-money, iPod, and Wii were found to be the best three, in these voting. Then the Author discusses the nature of these big hits one by one in the following two slides (below). |

As shown in the above slides, E-money and Wii are characterized as Service-oriented innovation, while iPod as New-business-oriented innovation. The descriptions of the nature of these Best Three products are interesting: (1) In order to realize such products, Innovators don' use new technologies but existing technologies. (2) Innovators realize radical innovation in service or business field.

The Author's (yet tentative) conclusion is interesting (slide (right)). Since the Author's Japanese slide seems more informative, I would like to translate it into English here:

The approach for matching the technology development (or evolution) toward the society evolution is important.

Namely, in the creation stage of innovation, matching the technology toward the trends of near-future society seems to be the key to success, while the technology to be matched may be either application of existing technologies or challenges of new technologies; the origin of the technology may not be so essential in this relation.

Now the Author discusses the Mega Trends in the current stage of Japanese society. There are a number of mega trends as shown here, and many more not shown here explicitly. Such mega trends give us various Latent Required Function (LRF) which suggest new possibilities of business activity and also pose various Latent Contradictions (LC) which urge us to solve for new opportunities of radical innovations. This type of diagram seems to be useful for further consideration.

On such a basis, the Author shows the perspective of Innovation-oriented TRIZ activities, in the slide (right). The bottom half is related to the activities for improved product planning, which try to meet the VOC (Voice of Customers) in the existing market by using VE and QFD approaches in the planning phase. For the purpose of planning next-generation products, it is essential to understand 'Latent Required Functions', on the basis of the (mega) trends of society and technology. For this process to predict the VOC in near future, Innovation-oriented TRIZ need to be used, the Author says. In realizing such a plan of next-generation product, there can be various 'Latent Contradictions'; thus they need to be grasped and solved by utilizing TRIZ thinking, as shown in the side.

[*** The positioning of 'Latent Contradictions' is not clear to me. I recall that both Boris Zlotin and Darrell Mann, in their Keynote Lectures at Japan TRIZ Symposium 2009, placed possible contradictions among the mega trends (i.e., 'Latent Contradictions' in Sawaguchi's term) at the key to finding the need of innovation. Thus 'Latent Contradictions' need be understand before the next-generation product planning, even though they need to be solved after planning. Probably, the meaning of 'new generation' products may be different between this and those articles.] [** Sawaguchi, Dec. 20, 2004: Please refer to the full paper, i.e., Manabu Sawaguchi: "A Study of Systematic Innovation based on an Analysis of "Big Hits" ", ETRIA TFC2010, Nov. 3-5, 2010, Bergamo, Italy.]

The following two slides (below) discuss further on the useful technique for Technology Prediction, especially the use of four aspects. The conclusion part is the same as shown in the previous slide.

Shinsuke Kurosawa, who has retired from SANNO Institute of Management last spring, gave an Oral presentation [J08, O-11]. His title was "What are “The Laws of Systems Evolution” – TRIZ, Phenomenology and the General Systems Theory". This presentation discusses the basis of TRIZ methodology. The Author's Abstract is quoted here first:

The author discusses plans to strengthen TRIZ theory regarding two of its fundamental issues;

The Laws of Systems Evolution are the foundation of TRIZ. However, the author cannot agree with the TRIZ community's general understanding that the laws rule the Objective World just like the Laws of physics. In author's understanding there is a transcendental and dynamic organic structure in the human consciousness just like there is an organic structure in the human body when a person is born. The author tries to identify what the set of TRIZ Laws of Evolution discloses about the structure of consciousness.

The System is one of the fundamental concepts of TRIZ. In 1950s Ludwig von Bertalanffy founded the General Systems Theory. Many of his ideas are applicable to TRIZ systems. But as long as the System is understood as an object in the Objective World, it is not possible to realize how such thing as General Systems can be conceived. The author tries to identify what are the TRIZ systems in the above mentioned structure of human consciousness.

Since this presentation is basic and philosophical, I will quote his slides without adding any comment. As you might know, Shinsuke Kurosawa is a very valuable member in the TRIZ community in Japan who is fluent both in Russian and English languages.

The slide (below-left) shows the purpose of the Author's present study, and the slide (below-right) is the outline of the presentation.

By examining Altshuller's paper "History of ARIZ Development" (1986) closely, Kurosawa summarizes the 'TRIZ Discoveries' as shown in the slide (below-left). He then poses questions to 'TRIZ Discoveries', as shown in the slide (below-right).

For the next step of his study, the Author shows his perspectives in the slide (right).

Then the Author gives his hypothesis, as shown in the slide (below-left), on the proposed structure of systems evolution. [A keyword here is 'transcendental': i.e., 'going beyond human knowledge, understanding, and experience; impossible to discover or understand by practical experience or reason (according to "Longman Dictionary of Contemporary English", New Edition).]

The Author writes, in the slide (below-right), he is proposing a phenomenological approach to understand the structure of systems evolution, in contrast to the traditional TRIZ approach based on materialism.

In the slide (below-left), the Author makes a comment on the concept of the "System". In his final slide (below-right), the Author discusses the methodological merits of his phenomenological approaches.

*** This presentation by Shinsuke Kurosawa is valuable in discussing and clarifying one of the basic issues in the philosophy/methodology of TRIZ. We wish the Author writes down this work into a full paper in the near future.

KyeongWon Lee (Korea Polytechnic University, Korea) [E07, O21] gave an Oral presentation with the title of "Quick TRIZ Process and the Related TRIZ Activities in Korea". His Abstract s quoted here first:

Author has developed the "Quick TRIZ" process showing contradictions of a problem into the modified conflict diagram in TOC (Theory of Constraints) visually. Some cases including non technical areas show the effectiveness of the process for TRIZ beginners and specially, general persons in non technical fields. The "Quick TRIZ" process is compared to the simplified TRIZ process such as USIT and ASIT. In this paper, the related TRIZ activities in Korea related to the "Quick TRIZ" are presented.

The Author's representation model is shown in the slide below-left. For demonstrating the use of his method, the Author has shown two case studies. His second case shown in the slide (below-right) is a problem related to an air injection gun for cleaning dust; because of the blown dust with oils, the workers have to wear masks on face.

By representing this problem on the diagram (see slide below-left), one can recognize the 'negative condition' of injecting air to be 'no injecting air' or further 'suction of air'. Now the conflict is recognized as a Physical Contradiction in TRIZ, the separation principle (on condition, in this cases) is applied to obtain the conceptual solution, i.e., an air injection gun switchable into an air suction nozzle. (The Author showed a slide of solution prototype in his presentation, but it is not recorded in the Proceedings.)

Hongyul Yoon (TRIZ Center, South Korea) [E03, O-17] gave an Oral presentation with the title of "OTSM-TRIZ Guide to Increase Effectiveness of Root Conflict Analysis". His Abstract is quoted here:

Root Conflict Analysis is adopted most frequently in engineering and research problem solving not only through TRIZ but also through the other problem solving tools. Compared to the popular use of it, its effectiveness seems poor, which the author defines as the degree to help the problem solver to transform the initial problem situation into clear description of simple problems. The author tries to offer a general process of how to deploy RCA more effectively through the guide of OTSM-TRIZ. First, ENV model is formulated to identify the initial harmful phenomenon as the target. The Multi-Screen Thinking based on OTSM-TRIZ leads the next step to provide an overview in order to reduce psychological inertia and increase objectiveness of the perception. 3 Postulates of TRIZ are applied as a way adapted by the author to get proper problem models to Substance Field Model.

A key to understanding the Author's intention is the definition of 'Effectiveness' (slide left-upper) in contrast to 'Efficiency' (slide left-lower) of the Root Cause Analysis (RCA). In his sense, for using the RCA method, efficiency in obtaining an RCA diagram is less important than the effective use of a resultant RCA diagram. Thus he pursues a new representation of RCA, and proposes the 'Ideal Cause Effect Chain Model' as shown in the slide (below-right). As the background the Author assumes basic OTSM-TRIZ concepts, including Multi-Screen Thinking (MS Thinking), Element-Name of Feature-Value of Feature (ENV) model, Su-Field modeling/Inventive Standards, Separation Principles, etc.

The following two slides (below) describe how to use the resultant Cause Effect Chain Model. In case of non-conflict problem model (see slide below-left), for preventing a 'Status' event in the chain one may build a Su-Field model and search for some solution idea by using Effects DB, Function Oriented Search (FOS), etc.; whereas for preventing an interaction event one may use the Su-Field modeling and Inventive standards. In case of a conflict problem model (see slide below-right), the conflict situation may be solved by applying Separation Principles and 40 Inventive Principles, etc., the Author says.

The slide (below-left) shows the steps for obtaining the Cause Effect Chain according to the model described so far. The Author demonstrated an example of using this method, referring his TRIZ Journal article (2008). In conclusion, the Author gives his Summary in the slide (below-right). According to a recent communication with the Author, he wants to emphasize that the main idea of the "Idea Cause Effect Chain Model" cannot be understood without understanding of the ENV model.

Masahiro Kuwahara (IDEA Ltd.) [J01, O-5] gave an Oral presentation with the title of "How to Make Good Concepts from Your Ideas Created by TRIZ". Here is the Author's Abstract.

TRIZ is a strong idea process where ideas to solve technological problems are invented. Up to now, I have explained how to clarify the root cause, how to formulate the contradictions hidden there, how to advance by imaging the best form of future systems, etc. in order to use TRIZ more effectively.

This time, I will present the way of thinking and method how to systematically select and unite the many ideas thus generated using the improvement of the electric shaver as an example. In the past, “good ideas” have been extracted only by the goal attainment level in the QCD aspect for selecting excellent ideas, but this time, I will explain about “making ideas effective,” with which you can more effectively shape into a realistic/strategic concepts by applying affinity diagram and Pugh’s concept selection method and taking in the ideality evaluation thought of TRIZ. This approach may be understood by an analogy of making up a delicious dish from all the ideas, imaging them as cooking ingredients.The Author is an active consultant specializing in TRIZ. The presentation was given in Japanese and no English slides were provided in the Proceedings. I have translated one of the Author's slides into English for this Personal Report. The slide (below) illustrates the general scheme of his approach (and of this paper).

The focus of the presentation is how to use a (large) number of ideas generated by TRIZ (through steps 1 and 2). The Author demonstrate the processes as (a) Classify the ideas into groups in the sub-sub-system level and get the overview of the whole ideas, (b) Try to combine the ideas to generate alternative solutions in the sub-system level, (c) Combine the sub-system level solutions into system level conceptual solutions which may be able to achieve the original goal, and finally (d) Build up a development road map (or scenario) having multiple conceptual solutions with the scope of short, medium, and long terms. This paper explains well about the general approach taken by the consulting firm, IDEA Ltd. for many years.

Shinichi Matsueda (West Japan Railway), Satoshi Hirono (OMRON), Toshiaki Masaki (Nitto Denko), Makoto Unno (Kawasaki Heavy Industries), Kazuyasu Ikeda (Sekisui Engineering), et al. [TRIZ Spreading/Use Study Group of Japan VE Association Kansai Branch] [J15, O-20] gave an Oral presentation with the title of "Study of Development-type TRIZ tool (part 4) – Case Study on Substance-Field Analysis / Standard Inventive Solutions –". This TRIZ Study Group in Japan VE Association started in 2003 and has been working actively with about 20-25 engineers who voluntarily coming from various industries. This presentation is the Part 4 of their joint work which have been reported annually in the TRIZ Symposium since 2007. The Authors' Abstract is quoted here.

In Japan VE Association Kansai Branch, as part of VE technical research, "TRIZ Spreading/Use Study Group" was established in 2003 focusing on TRIZ technique as a means for new value-added creation. With the intention of using VE and a variety of TRIZ techniques in fusion, we have examined various related TRIZ tools extensively. In our Study Group, we consider applications of specific tools expecting to crystallize the method of application and to utilize efficiently at the new product concept planning phase and technical development phase for new value-added creation especially at the manufacturer’s side. Since 2006, case studies have been done for precise understanding of various TRIZ tools’ features, and this activity is planned to be continued till 2011. In this presentation of our 4th case study, the implemented content of last year’s case study on “Substance-Field analysis / Standard Inventive Solutions” together with the practical and useful knowledge obtained from it will be reported.

As written in the Abstract, the Group have been working on detailed examination/discussions of TRIZ procedures using a case consistently. They already reported on the procedures of Problem definition, Product Analysis, Cause-effect analysis, USIT problem analysis, (Technical contradiction, report skipped) and Physical contradiction. So this year, they are reporting on their study/discussion (done from May to October, 2009) on Su-Field Modeling and usage of Standard Inventive Solutions. [*** This presentation was done in Japanese only, without making slides translated into English. Because of the importance of this presentation, however, I have translated 7 of 54 Japanese slides into English for the present review.]

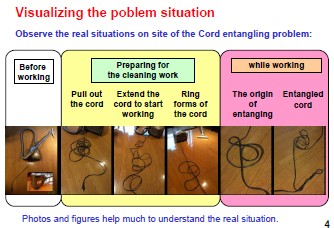

The case they have been using consistently is how to develop an new (near- future) product of electric vacuum cleaner by solving the two well-known problems as shown in the slide (below-left). Of the two problems worked on in parallel, the Cord Problem is used for illustration in the present report. The cord is apt to get entangled during the room cleaning work, as shown in the photo (left in the slide below-left). The Study Group made four trials of using the Su-Field Modeling method. The slide (below-right) is a record of an initial step in the first trial. The problem is visualized in a basic, simplified situation.

As the basis of the Su-Field Modeling method, the Authors adopted the one in Darrell Mann's textbook "Hands-On Systematic Innovation", as illustrated in the slide (right). After four times of trials and follow-up discussions, they say that to follow the process carefully step by step is important and useful for revealing different view points and generating a variety of solution ideas.

Then the Authors have reported their findings by using 24 slides in Japanese. Only 4 slides of them are shown below.

One of their most basic findings in this case is the importance of observing the real problem on site and visualizing it especially in the time sequence. The photos shown in the slide (below-left) are useful for understanding the problem. On the basis of this understanding, the problem models should made in several different ways, in various stages of using the cleaner. The slide (below-right) shows three functional models, corresponding to the three main stages, i.e. the preparation, working, and finishing stages. Each model is represented in a functional diagram, typically used in the Invention Machine Inc.'s software tool.

These functional diagrams are next represented in the Su-Field Model. Several Su-Field diagrams are made as illustrated in the slide (below-left) from different view points. Different diagrams can tell us different things, and hence can stimulate us to generate different, useful solution ideas, the Authors say. The existing representation methods, originally from Classical TRIZ, are not easy to understand, the Authors say. And hence, they tried to make their own way of representing the model, especially the Field in the model. As shown in the slide (below-right), their representation method is essentially the functional relationship diagram with the addition of the Field description along the function arrow. At the bottom-right diagram, they have shown their final understanding that the Cord gets twisted by the function of the Cord itself.

Hideaki Kosha (*), Yuji Mihara (Creative Technology Institute), Noritaka Nakayama (Konica Minolta Technology Center), Toru Nakagawa (Osaka Gakuin University), Kouichi Nakamura (*), Hirotake Makino (*), Kazushige Aoki (*), Hideki Oomori (*), Tatsuhiko Atsuta (Hitachi Maxell), and Tsuyoshi Todome (*) [(*) MPUF-USIT/TRIZ Study Group] [J11, P-A3] gave a Poster presentation with the title of "Study on USIT Operators Application Examples (2)". This Study Group is also a group of engineers voluntarily coming from different industries. The group started in April 2007 after a proposal by myself and Yuji Mihara, as introduced in. This presentation is a work done by one of its two current subgroups. [*** Nakagawa is one of the co-authors. But I must confess that this presentation should have been brushed up in some points.] The Authors' Abstract is quoted here:

The aim of our study team is to offer a guide for USIT users to utilize the USIT Operators. The USIT Operators were developed as clues to generate technical ideas from the viewpoint of Object-Attribute-Function relationship.

From more than hundreds of reverse engineering analyzed examples, we realized the following:

1) Technical problems of familiar products seldom meet “functional level unstable”

2) Descriptions of plausible root causes vary between members -> difficult to standardize

To complete USIT Operators Application Examples, we continue these works.

1) Expand the scope of examples

2) Make out the guide for extracting plausible root causes

3) Verification of USIT Operators Application Examples

The bases of the work are formed by accumulating good sample solutions of applying USIT Operators (See the slide (below-left)). Such samples need not to be original cases of application (i.e. where the inventor knew about the USIT Operators and applied them intently in driving the idea). Thus hundreds of good solutions in various products in various industries are collected and analyzed in the reverse way to reveal what kind of problem is handled and what kind of solution generation method is applied in terms of the USIT Operators. For this accumulation work a documentation form was prepared and many documents were reviewed by the Study Group. Then each case of applying an USIT sub-operator is located in the "Problem-Viewpoints Index Matrix" (slide below-left), just like G.S. Altshuller made his Contradiction Matrix. The structure of the Authors' Problem-Viewpoints Index Matrix was explained in the Part 1 Report last year. The problems are classified in a hierarchical manner into 16 categories, corresponding to the nature of the problem in functional achievements (i.e., insufficient, excessive, unstable, and harmful) and then in the causal aspects in terms of distribution/consumption of energy/things etc. The rows represent the USIT sub-operators. Once the Problem-Viewpoints Index Matrix is established with a large number of cases (currently about 200 cases completed), then the usage of it is rather straightforward (see slide below-right). For any problem, the user should consider the nature of the problem and find its proper category (among 16). Then the number of cases (or any other qualitative indicator) in the cell of the Problem-Viewpoint Index Matrix will guide the user to the USIT Sub-operators which are found most frequently used in good examples of problem solving. The sample cases accumulated and classified in the knowledge base will be helpful for the user to understand how to use the USIT sub-Operators in the his/her own case.

[*** Sample cases need to be analyzed carefully and accumulated more and more, but the framework of the knowledge bases and the Problem-Viewpoint Index Matrix has been established well already, we suppose. Thus this work is going to be reported in the form of a full paper in the near future.]

| Top of this page | Review of Sawaguchi's lecture | Sawaguchi's presentation => JTS |

Sawaguchi's page |

Review of Kurosawa's presentation | Rev. K.W. Lee | Rev. H.Y. Yoon | Rev. Kuwahara | Rev. Matsueda | Rev. Kosha | Japanese page |

Last updated on Mar. 13, 2010. Access point: Editor: nakagawa@ogu.ac.jp