| Concept Development of a Variable Compression Ratio Engine Using TRIZ | |

| Hong-Wook Lee, Won Gyu Kim, Myung Rae Cho, Jin Woo Cho, Sang Hee Lee (Hyundai-Kia Motor Company, Korea) | |

| The Sixth TRIZ Symposium in Japan, Held by Japan TRIZ Society on Sept. 9-11, 2010 at Kanagawa Institute of Technology, Atsugi, Kanagawa, Japan | |

| Introduction by Toru Nakagawa (Osaka Gakuin Univ.), Mar. 21, 2011 | |

| [Posted on Sept 19, 2011] |

For going back to Japanese pages, press buttons.

Editor's Note (Toru Nakagawa, Sept. 18, 2011)

This paper was presented by Hong-Wook Lee a year ago in an Oral session at the Sixth TRIZ Symposium in Japan, 2010

. Presentation slides have been posted in PDF both in English and in Japanese translation (by Toshiaki Masaki) in the Members-only page of Japan TRIZ Society's Official Site since last March. For wider circulation, they are now posted here publicly under the permissions of the Authors.

Last March I posted an introduction to this paper as a part of my Personal Report of the Symposium

. The excerpt is posted here again in English.

This paper is an excellent record of TRIZ thinking for developing improved solution concepts further and further. The Authors learned the merits of Variable Compression Ratio (VCR) Engines, which are of course patent protected. Thus they circumvented the patents by use of Trimming, strengthen the resultant idea with 'Antidote', solved a secondary problem with ARIZ, and extended the concept further with the use of Function oriented search.

| Top of this page | Abstract | Slides in PDF |

Slides in Japanese, PDF |

Nakagawa's Introduction | Nakagawa's Personal Report of Japan TRIZ Symp. 2010 |

Japan TRIZ Symp. 2010 |

Japanese page |

[1] Abstract

Concept Development of

a Variable Compression Ratio Engine Using TRIZHong-Wook Lee, Won Gyu Kim, Myung Rae Cho, Jin Woo Cho, Sang Hee Lee

(Hyundai-Kia Motor Company, Korea)Abstract

The variable compression engine means that the compression ratio of the engine can be controlled at each engine operation condition. When the more power of engine is needed during high load, the compression ratio is decreased, and when the higher efficiency is needed during low load, the compression ratio is increased. Many companies have been carrying out their own research in to VCR Engines, so that each company has different type of VCR engine, but so far VCR engines have not been mass-produced. In this study, TRIZ is applied to develop new concept of VCR engine. Various tools of TRIZ have been used in this study: “Function analysis” is applied to analyze previous VCR models, and “Trimming” to make new contradiction, then “ARIZ” to solve this problem.

Extended Abstract

Environmental awareness and fuel economy legislation have resulted in greater emphasis on developing more fuel efficient vehicles. As such, achieving fuel economy improvements has become a top priority in the automotive field. Companies are constantly investigating and developing new advanced technologies, such as hybrid electric vehicles, plug-in hybrid electric vehicles, and fuel cell vehicles. At the same time, significant research and development are being performed to improve fuel efficiency of conventional internal combustion engine.

One of challengeable items for the conventional engine will be “variable compression ratio (VCR) engine” which the compression ratio of the engine can be controlled at each engine operation condition. When the more power of engine is needed during high load, the compression ratio is decreased, and when the higher efficiency is needed during low load, the compression ratio is increased. This is one of good examples of “Separation in Time” in TRIZ. VCR engine with turbo-charger improves 20~30% of fuel consumption in comparison with the same power of naturally-aspired engine as shown in Fig.1.

Fig. 1. Fuel Consumption with VCR Engine [1]

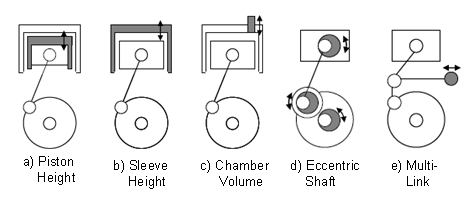

Many companies have been carrying out their own research in to VCR Engines, so that each company has different type of VCR engine as shown in Fig.2, but so far VCR engines have not been mass-produced.

Fig. 2. Various VCR Configurations [2]

In this study, TRIZ was applied to develop new concept of VCR engine. First step was started to circumvent previous patents of VCR engine with TRIZ tools of “Function analysis” and “Trimming”, then following steps were focused to strengthen the idea with “Antidote Strategy” and “ARIZ”. Final step was to expand ideas to other application with “IFOS”. As a result, several concepts of VCR engine have been obtained successfully by using TRIZ.

Reference

[1] M. Schwaderlapp, K. Habermann and K. I. Yapici, 2002, Variable Compression Ratio - A Design Solution for Fuel Economy Concepts, SAE 2002-01-1103.

[2] S. Ishikawa, M. Kadota, K. Yoshida, K. Takahashi and S. Kawajiri, 2009, Advanced Design of Variable Compression Ratio Engine with Dual Piston Mechanism, SAE 2009-01-1046.

[2] Presentation Slides in PDF

Presentation Slides in English in PDF

(18 slides, 775 KB)

Presentation Slides in Japanese in PDF

(18 slides, 479 KB) (Japanese translation by Akira Mochizuki (Nissan Motors) and Toru Nakagawa (Osaka Gakuin Univ.))

[3] Introduction to the Presentation (by Nakagawa)

Excerpt from:

Personal Report of The Sixth TRIZ Symposium in Japan, 2010, Part D

by Toru Nakagawa (Osaka Gakuin University),

Posted on Mar. 21, 2011 in "TRIZ Home Page in Japan"

Hong-Wook Lee, Won Gyu Kim, Myung Rae Cho, Jin Woo Cho, and Sang Hee Lee (Hyundai-Kia Motor Co., Korea) [E11, O-6] gave an Oral presentation with the title of "Concept Development of a Variable Compression Ratio Engine Using TRIZ". This presentation was originally given in the 'Global TRIZ Conference in Korea 2010 (KoreaTRIZCON 2010)' in March 2010, and we are happy to have this excellent presentation again in our Japan TRIZ Symposium 2010. Dr. Hong-Wook Lee made his talk in Japanese, to our surprise; he had studied for 2 years at the Graduate School of Kyoto University, Japan. The Authors' Abstract is quoted here:

The variable compression engine means that the compression ratio of the engine can be controlled at each engine operation condition. When the more power of engine is needed during high load, the compression ratio is decreased, and when the higher efficiency is needed during low load, the compression ratio is increased. Many companies have been carrying out their own research in to VCR Engines, so that each company has different type of VCR engine, but so far VCR engines have not been mass-produced. In this study, TRIZ is applied to develop new concept of VCR engine. Various tools of TRIZ have been used in this study: “Function analysis” is applied to analyze previous VCR models, and “Trimming” to make new contradiction, then “ARIZ” to solve this problem.

In the first slide (right) the Authors introduce the research target of their study. It is to develop "Variable Compression Ratio (VCR) engine". The slide explains the concept of Compression Ratio (CR). There is a common technical contradiction in the conventional engine that higher CR is desirable for higher thermal efficiency but undesirable because of the decrease in engine power due to Knocking.

The known solution of this Technical Contradiction is the "Variable Compression Ratio (VCR) Engine (slide (right)). It can be understood, in TRIZ terms, as the solution obtained with Separation in Time. The VCR engine can vary and control the CR according to the engine operation condition. In case of low load & speed, high CR is used for higher engine efficiency, whereas in case of high load & speed, low CR is used for larger engine power.

Various types of VCR engines have already been developed by other companies. So the Authors carried out bench marking on them (see slide (right)). Among the six types of VCR engines, they have concluded that the Multi-Link Rod-Crank type is the most suitable from the viewpoint of mass-production. The known models of the type were of course patent protected by the developer. Thus the next problem for the Authors was how to circumvent the patent. For this purpose they used TRIZ.

The typical way of using TRIZ for patent circumvention is to apply the Functional Analysis of the patented system and then to trim the key element(s) in it. Thus they trimmed (or removed) the control link in the system of the existing patent. The slide (right) illustrates their thinking process in detail. [*** This presentation is very valuable in this feature as a case study. We can vividly trace and learn how the Authors thought in their mind.] They considered the function of the (trimmed) control link and found that they should just manage to reproduce the trajectory of the control pin. Thus they devise the Control Slot (controlling the trajectory of the pin) and attached it at the side of the cylinder block. (IDEA-1)

The strength of this work is that the Authors went further to think better ideas, as shown in the slide (right). They tried to strengthen the idea further by trimming the Control Pin. They found the Upper Pin could also work for controlling its trajectory with a Control Slot. Thus they have obtained a second solution of new VCR engine, IDEA-2, as shown in the slide.

Another route of their thinking was to consider about possible problems in the new solution. One of the possible problems in IDEA-1 wa found the manufacturing precision of the Control Slot. If the Slot is too tight, the friction between the pin and the slot will cause inefficiency of the engine. If the Slot is too loose, the motion of the piston can not be controlled well. They tried to change the shape of the Pin from round to square, but found the idea is not good enough. Then they got the idea of using a bar and a holder. They have found a straight Control Bar is useful, as shown in the upper-right figure in the slide. (IDEA-3)

Further, the Authors tried to expand the function of the Control Slot to other applications. As shown in the slide (right), they have obtained a new concept of "Variable Displacement Engine" (instead of Variable Compression Ratio Engine) using the Control Slot. By setting the Control Slot at different positions, the displacement length of the piston can be changed; large, small, and even zero displacement lengths. (IDEA-4) [*** I do not know for what purpose this change is useful.]

The Authors illustrate the results of their idea generation process. They have worked for the development of new types of VCR engine. Their first step was to circumvent other company's patents, by using the Trimming method. Then they went ahead to strengthen the idea, to solve expected problems in the new solution, and to further expand the function of VCR. [*** The strength and value of this presentation is the Authors' attitude to think and develop further and better solution concepts, I think.]

The Authors conclude their presentation with the slide (right). They have used various TRIZ methods as listed here and explained in their previous slides cited above.

[*** This is an excellent case study from which we can learn a lot about how to think. I wish that the PDF file of their presentation slides may be posted in this Web site under the permission of the Authors and their company, Hyundai-Kia Motor Co., Korea.]

[Note: We have now posted the original presentation slides in the present Web site in English

and in Japanese

. (Sept. 19, 2011)]

| Top of this page | Abstract | Slides in PDF |

Slides in Japanese, PDF |

Nakagawa's Introduction | Nakagawa's Personal Report of Japan TRIZ Symp. 2010 |

Japan TRIZ Symp. 2010 |

Japanese page |

Last updated on Sept. 19, 2011. Access point: Editor: nakagawa@ogu.ac.jp